What Is a UL-Approved Mod Shop? And Why It Matters

Facilities require equipment that is not only robust but also strictly compliant with safety regulations to protect personnel and expensive machinery, and Underwriters Laboratories (UL) standards serve as the benchmark for this reliability. When a project requires a custom motor starter, control panel, or power assembly, the distinction of a UL-approved mod shop becomes a critical factor in the operation's success.

Understanding UL Listing, Certification, and Approval

The acronym UL stands for Underwriters Laboratories, an organization that develops rigorous safety standards for electrical products. Understanding the nuances of these terms is vital for engineers and facility managers. A UL listing signifies that a representative sample of a product has been tested and meets specific safety requirements. UL certification is often used interchangeably, though it technically refers to the broader process of verifying that products meet these global standards.

A common misconception involves the term UL-approved. While frequently used in the industry, UL does not technically "approve" a product; rather, it lists or classifies it based on its adherence to established safety benchmarks. The UL rating provides specific data regarding the environment or load a component can handle. In industrial environments, using UL-listed components helps ensure the entire system maintains a high standard of protection against electrical failure and fire hazards.

What Is a UL-Approved Mod Shop and What Can It Do?

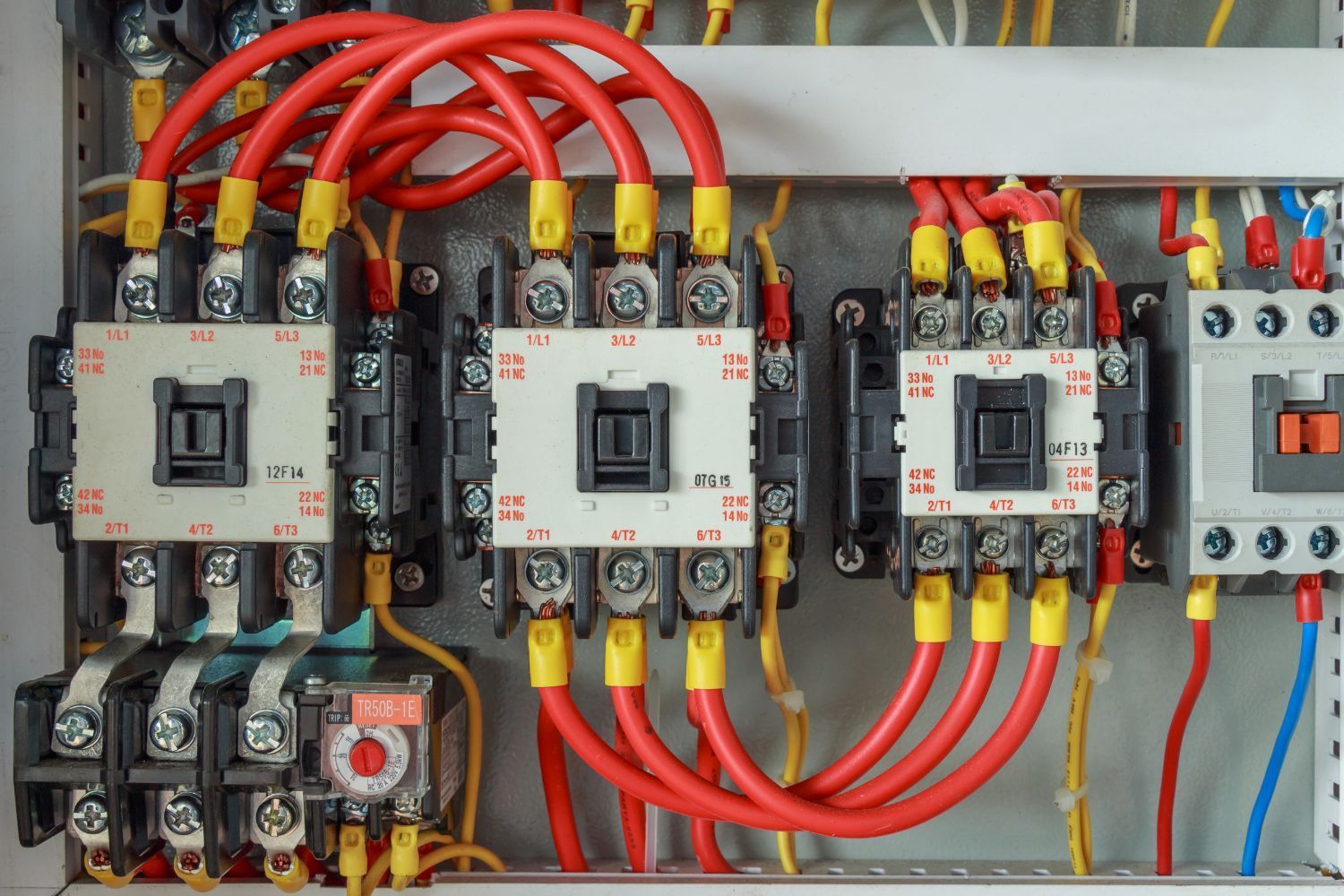

A UL-approved mod shop is a specialized facility authorized to modify UL-listed products without voiding their original safety certification. Standard panel builders may assemble components, but a mod shop has undergone a rigorous evaluation of its processes to ensure that any changes made to a device, such as adding pilot lights, selector switches, or custom enclosures, maintain the integrity of the original UL listing.

At Teal Electric Company, our mod shop capabilities enable customization of Siemens motor starters, NEMA-rated enclosures, and control-circuit protection. We can integrate finger-safe technology, micro-automation, and specialized function relays into existing frameworks. Because the process is conducted under strict UL guidelines, the final assembly carries the required certification for immediate installation in commercial or industrial settings.

Why UL-Approved Mod Shops Add Value for Industrial and Commercial Operations

The primary advantage of utilizing a UL-approved mod shop is the assurance of code compliance. When an inspector arrives at a facility, seeing a UL-certified assembly drastically reduces the risk of project delays during commissioning. Field modifications often raise safety concerns or lead to failed inspections, whereas a shop-modified component arrives ready for service.

Speed is another significant factor. By maintaining a large stock of Siemens components, Teal Electric Company can execute modifications rapidly. Rather than waiting for a factory-built custom order that may take months, a mod shop can provide a tailored solution in a fraction of the time. Furthermore, we provide real-time managed inventory solutions that help our clients reduce excess in-house stock while ensuring they have access to emergency repair parts on short notice.

Why Teal Electric Company’s UL-Approved Mod Shop Makes a Difference

Teal Electric Company brings over 30 years of industry experience and a deep understanding of the industrial supply chain. We are a dedicated industrial distributor serving contractors, engineers, and facility managers.

Our in-house mod shop offers complete control over the quality of custom motor starters and critical power systems. We leverage our relationships with Siemens to ensure every modification is performed with factory-trained precision. By choosing Teal Electric Company, you gain a partner that understands the technical specifications of Siemens products and the complex offerings of selectable trip curves in modern breaker technology. Want to learn more about our products?

Contact us today.

Image credit: // Shutterstock // RobinBaranov